Vegetable Chilling with Vacuum Cooling

Preserving vegetables for transport is a unique challenge the food processing industry faces. Once harvested, produce has a limited window of freshness. It is crucial to get produce to grocery stores in the freshest possible state.

Vacuum cooling is one method that is already in use and quickly becoming more widespread as food processing companies are realizing the benefits.

How Does Vacuum Cooling Work to Chill Vegetables?

In order to chill vegetables, you simply need a refrigeration system. So why not just put them in a giant refrigerator? Because a regular refrigerator would take too long to chill large quantities of vegetables. The produce would begin to rot before it ever gets to the store.

Vacuum cooling involves chilling the vegetables in a depressurized chamber. By lowering the pressure inside the chamber the air can cool much faster, and thus chill the vegetables much faster.

Why does decreasing air pressure allow the air to cool faster? Because the lower the air pressure, the lower the boiling point of water. Heat can be removed much faster in depressurized, dry air.

How are Ro-Flo Compressors Involved in Vacuum Cooling?

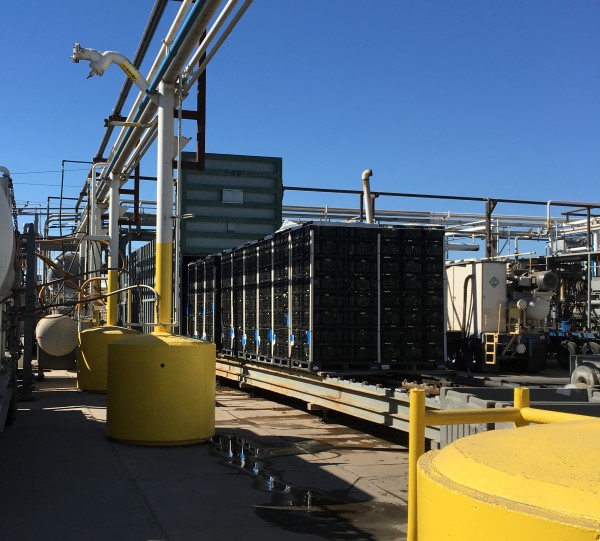

Ro-Flos operate as a vacuum pump, reducing the pressure within the chamber allowing for greater cooling capacity.

Benefits of Using an Industrial Food Processing Cooling System

Why is vacuum cooling becoming more and more prevalent in the food processing industry for handling produce?

- Fresher Vegetables. One obvious benefit is that vegetables stay fresher for longer periods of time and during transit. Food processing companies can chill vegetables immediately after harvesting to preserve them at their freshest point, preventing premature spoiling.

- No Risk of Freezing. Vacuum cooling removes the moisture from the air inside the cooling chamber, which prevents vegetables from freezing. Precise temperature control also plays a part in preventing freezing. The depressurization process allows for even cooling from the center and surface of the vegetables.

- Faster Cooling. Industrial food processing cooling systems can chill vegetables faster, reaching the desired temperature in as little as 30 minutes.

- Efficiency/Save Money. Vacuum cooling is extremely efficient, chilling larger quantities of produce in a shorter amount of time.

Ro-Flo Vacuum Compressors and Vacuum Pumps are Ideal for Produce Chilling

Industrial food processing cooling systems operate best using Ro-Flo vacuum vacuum pumps. This is due to their ability to provide a deep level of vacuum. The key to optimal vegetable chilling is fast depressurization for faster cooling.

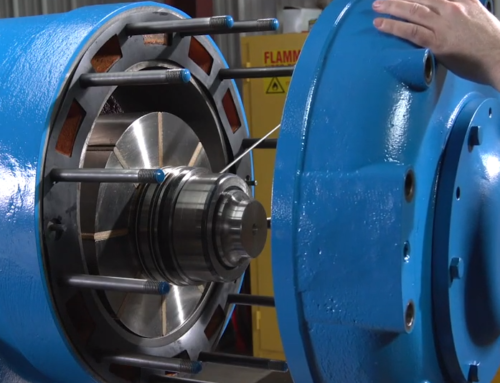

Ro-Flo products are robust and reliable, standing the test of time. Maintenance is straightforward and simple. A complete maintenance routine of a Ro-Flo vacuum pump can be completed in a single shift.

Dependable, Efficient Performance for When Time Matters

As soon as produce is harvested the clock begins to tick. There’s only so much time to get the product where it needs to go before it spoils. When time is of the essence, put your trust in a brand name you can count on to handle the job.