When you choose a Ro-Flo rotary vane compressor, you’re choosing a compressor design that stands the test of time. You’re also purchasing from a business that is committed to providing unparalleled customer support. Ro-Flo Compressors has also developed a state-of-the-art rotary testing facility that tests all types of rotating equipment utilizing ASME PTC, ISO, and API standards.

Ro-Flo’s Test Center and personnel have become experts in troubleshooting. Here are a few troubleshooting tips.

Why Temperature Matters for Rotary Vane Compressors

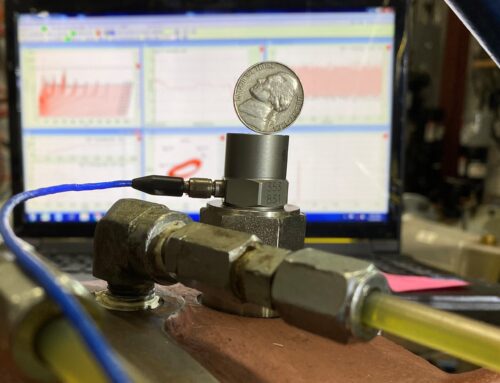

The key to troubleshooting is knowing your baseline, or normal operating parameters. Deviations from normal pressures and temperatures are a sign of process or machinery change; in fact, temperatures that deviate from normal are one of the first signs of machinery malfunction. The locations of these deviations can help pinpoint the location of the problem.

Normal operating temperatures are a function of the conditions of the application. To evaluate normal operation and establish a baseline, it’s necessary to record:

- Atmospheric pressure.

- Gas composition entering the compressor inlet flange.

- Gas flow rate entering the compressor inlet flange.

- Gas pressure and temperature at the inlet flange of the compressor.

- Gas pressure and temperature at the discharge flange of the compressor.

- Cooling fluid inlet and discharge temperatures.

How to Measure Temperature and Pressure

When measuring temperature and pressure, it’s important to gather the information as close to the rotary vane compressor flanges as possible.

The actual inlet pressure and temperature are often affected by clogged filters/mist pads, or faulty process controls. Similarly, actual discharge pressure and temperature can be affected by clogged discharge check valves, after coolers, or separator vessels.

A very useful tool in predicting operating parameters is the Ro-Flo Performance Software, which can be downloaded from our website by registered users.

Get Expert Assistance From Ro-Flo

If you’ve reached the extent of your troubleshooting capability and are still stumped, maybe Ro-Flo can assist. Ro-Flo’s state of the art Rotary Test Center provides expert diagnostics and repairs for all rotating equipment, including positive displacement compressors, centrifugal compressors, pumps, turbo expanders, gear boxes, and all support components and systems.

The Test Center uses the latest technology to diagnose issues and pinpoint the problem. Highly experienced engineers and technicians support the process and repair the compressor to like-new specifications. Contact us today to get started.